The end product of timber framing is what everyone knows and loves: the warmth of the wood, the details in the joinery, the stain, the massive beams overhead:

What happens before the finished product is where we at Vermont Timber Works come in. The idea for your timber frame may be in the very beginning stages–possibly a retirement home for a few years from now, or an addition to your existing home that you would like to put on in the future, or that timber frame barn for your shop. We can steer you in the right direction with regards to the species, framing style, joinery, finish, and all of the other details that go into your frame. We pride ourselves on our attention to detail, as we want to make sure that you get exactly what you envision in your timber frame.

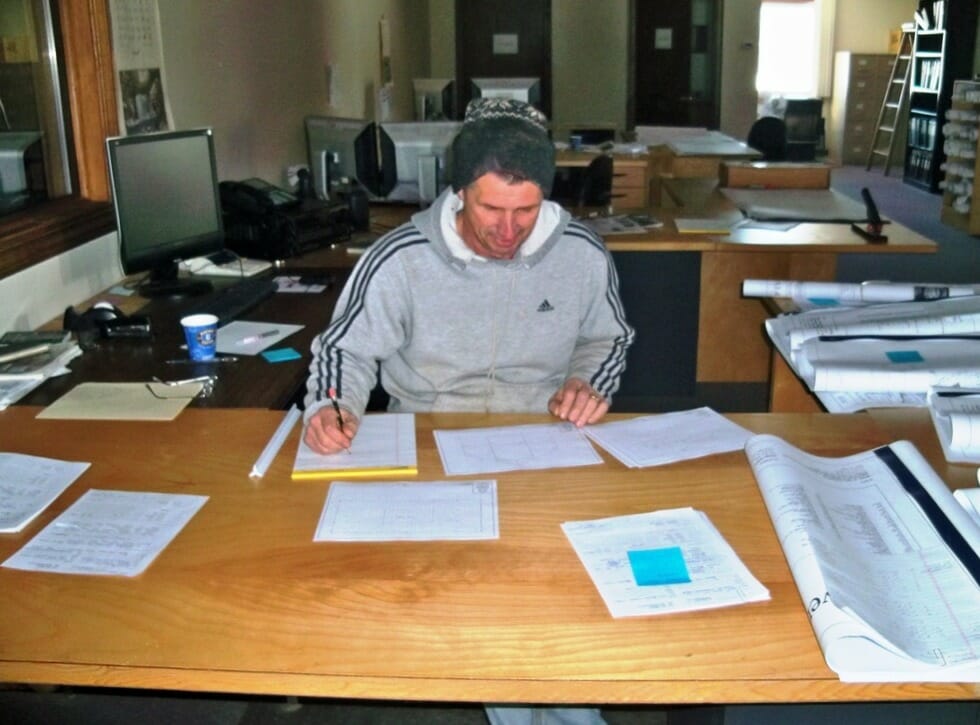

It all starts with your ideas–our estimator Rick looks at your project and will compile a material list and a list of questions to ensure we are on the same page with you and your architect, if you are working with one.

Once preliminary drawings are provided by our clients’ architects or after we complete a 3d preliminary design, the project goes to Richard, our estimator. He will often do a sketch then will take off a material list for pricing.

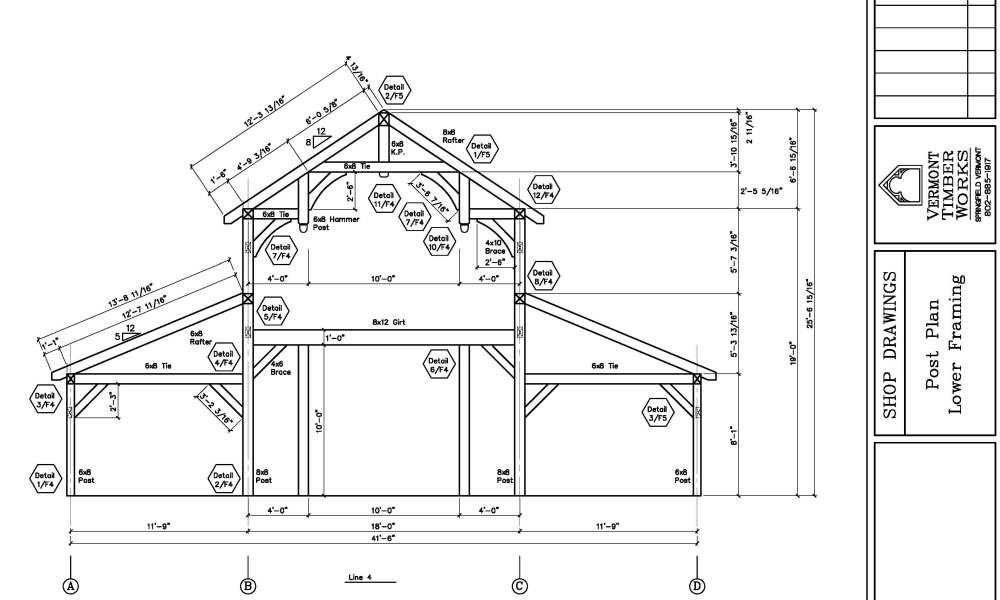

Once we enter into contract with you we will produce a set of shop drawings for your approval–another double check before we order your material. This set of shops will show you exactly what you will be getting from us–dimensions of timbers, roof pitches, truss profiles, etc.

Before the barn is build, detailed shop drawings are created. The drawings are sent to the client for design review, revised according to the job specifications and sent to the shop for fabrication.

Once you have approved the shop drawings we will order the material, which comes from a variety of mills around the country. Douglas fir comes from the Northwest, White Oak comes from either the South or the Mid West, Southern Yellow Pine from the South, Eastern hemlock and Eastern white pine from here in New England.

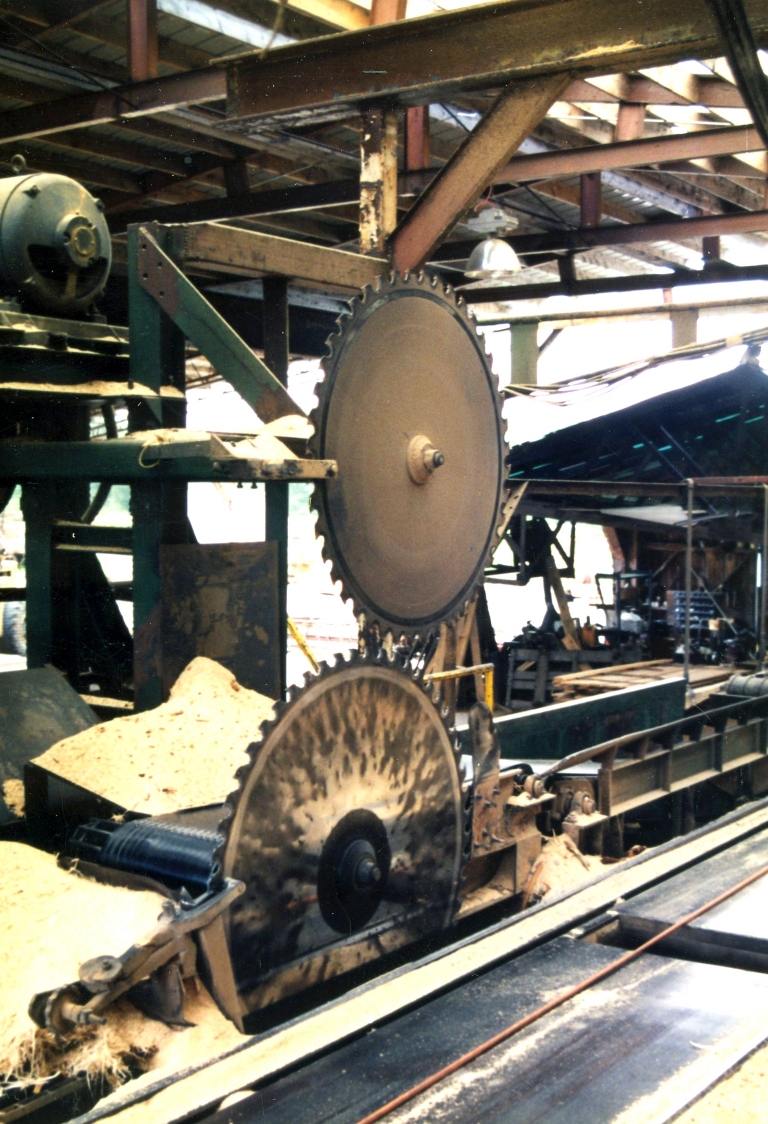

The Saws at the Mill

After their bark is stripped off, the raw logs are cut into square timbers.

Once the material arrives at our shop we begin our fabrication of your frame. We lay out your timbers according to the drawings, another important double check.

Once the timbers are laid out, our joiners do yet another double check on the timbers to make sure they are laid out correctly before we do any fabrication. The old saw of “measure twice, cut once” is very true, especially in timber framing where precision is pivotal.

Cutting a Detailed Joint With a Small Saw

Smaller saws are used to do the finer cuts.

After we cut all of the joints the timbers are then stained, which seals the timbers and gives them the desired hue that you have chosen.

Dark Wood Stain on Curved Braces

These arched braces are drying after receiving a coat of dark stain and a coat of urethane. Notice that all surfaces of the brace have been sealed. The final coat of urethane protects the timber and gives a nice finish.

Once the stain dries we organize your timbers and build packages to go on the back of a tractor trailer.

Finally, we load the timbers onto a tractor trailer to be delivered to your job site. You can opt for us to set the timber frame, or your contractor may be able to set the frame himself.

That’s it!

Thank you for stopping by our timber framer’s blog! If you have a timber frame project in mind, or any timber work questions, we invite you to get in contact, ask an expert, or share your thoughts in the comment section below.

Nice post Mike!!

Thank you for sharing this information on timer roof trusses. My wife and I are having a second house built and we would really like there to be timber roof trusses. We really like the look of them because it adds such a nice touch to the inside of the house. Like you said, “the idea for your timber frame maybe a possible retirement home.” That would be ideal! Thanks again.

Very clean web site, appreciate it for this post.