Well it’s been a couple of snowy, cold weeks in Vermont. When I woke up on Monday it was -15 degrees. That’s minus, i.e. below zero. I don’t think that even registers in Kelvin or Celsius. It was, as we like to say in Vermont, as cold as…well let’s just leave it as very cold.

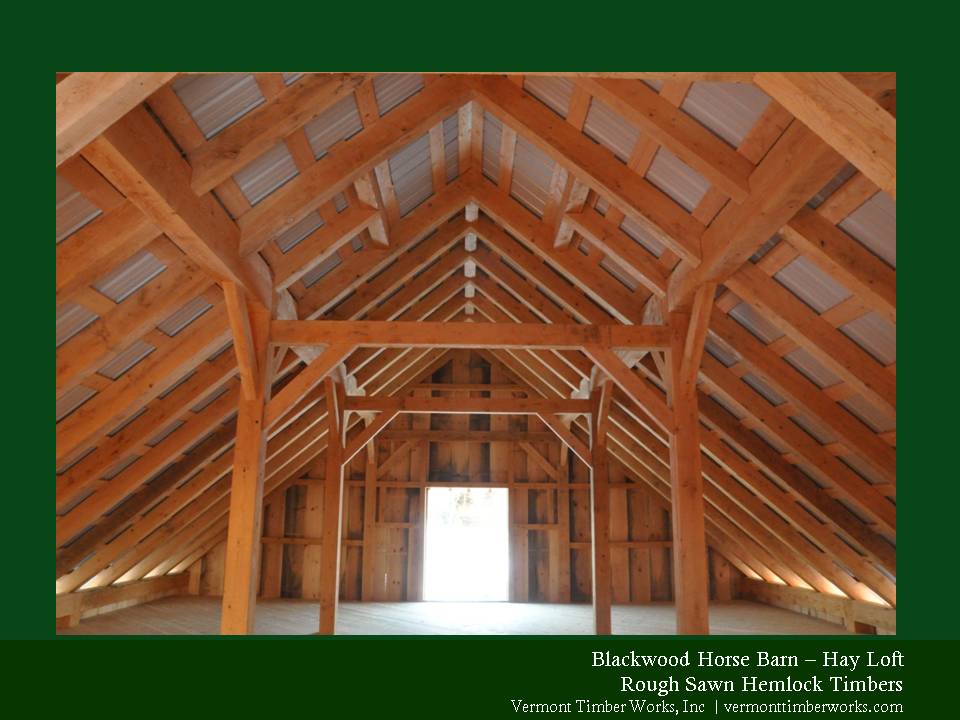

Speaking of Vermont brings us around to what, in my humble opinion, is the seventh coolest timber frame Vermont Timber Works has built, the Blackwood Barn in Rockingham, VT. You can see a video of the whole process (very cool time-lapse) at our website. Check out the rest of The Top 10 Coolest Timber Frames (According To Me) here!

This barn was actually one of two frames we built for our client (the other was the client’s residence). The site is gorgeous, on top of a hill with views to die for.

Our crew travelled to the site (which is not far from our shop in North Springfield) every day for the raising. We had already cut all of the joints (mortise and tenon, and assorted notchings) into the timbers in the shop, and had put a coat of finish on the timbers–standard practice for us. Since it is the same crew that cuts the frames as the one that assembles and raises the frame the guys know exactly which pieces go where. As you can imagine with timber framing there can be some serious head scratching as to which brace goes into which plate, etc.

The weather cooperated with us (for a change), and we had dry sunny days. It was autumn, so we didn’t get overheated, although the afternoons were about as perfect as perfect can get.

There I am with my Windham Volunteer Fire Co. t-shirt driving a peg home, which is a great feeling by the way.

After the main frame had been set we built the drive-through shed.

If memory serves me well we finished this frame within one work week.

The final beam being put into place is like that last piece of the jigsaw puzzle, when everything comes together.

When we were done with the timber framing the contractor finished the roofing and siding, and we went back a few months later to take some progress shots.

I thought this was a cool shot of the loft area, which was engineered to support the hay needed for our client’s horses. We engineer all of our frames so you don’t have to worry about your structure, either now or years from now.

Those wide plank pine boards are a really pretty contrast with our hemlock beams. I can honestly say that if I were a horse I would be very happy to call that barn my home.

Thanks for stopping by our timber framers’ blog! If you like this frame, or have any timber work questions, we invite you to get in contact, ask an expert, or share your thoughts in the comment section below!