Design/Build Construction

Design it, build it, done! If it were only that easy. Actually, sometimes it is. Design / Build is a wonderful choice for construction, and at Vermont Timber Works, we excel at it.

Let’s check out a residential, design/build timber frame! The Adirondack style home, pictured below, was a design/build frame. The Architectural design was done by Bonin Architects and the Construction Managers were McGray & Nichols. The timber frame shop drawings, engineering, joinery details, timbers cuts, timber finish, and the frame raising were all done by the Vermont Timber Works team.

Adirondack Style Timber Frame Home / Photo by Bonin Architects

We don’t use a CNC machine in Vermont Timber Works shop. All of our timbers are hand crafted by talented people. Mike is using a hand held band saw to cut a curve detail in the picture below.

Radius Detail.

Photo by Bonin Architects

This high end residential project is a great example of a design/build home!

Technical/Complex Construction

Some projects do not fit the design/build category. One project that comes to mind is the Nemacolin Ski Lodge, which was mainly lead time related. The more complex the design details are in a frame, the longer the timber frame process takes. The material for technical projects generally shouldn’t be ordered until the engineering is completed and the shop drawings are finalized and approved.

In this case, the timber sizes needed for the columns were going to take quite some time to source….So we took that part of the design, engineered it, and ordered the timber columns with added length, just in case. Columns that are too long are better than columns that are too short, unless you have that elusive wood stretcher…

Timber Columns Peeled

During the engineering process, first we thought about the columns, then we thought about the braces. We worked with the architect and engineer on record to use the braces to achieve a tree branch look. The braces needed to be laminated timbers for strength. The tip of the column and the braces connect to each other with a steel cap.

The laminated braces actually arrived before the columns, which were ordered first. This is when the lead time stress begins…..This project had a scheduled opening which we are working backwards from. Yikes!

On to the Entry.

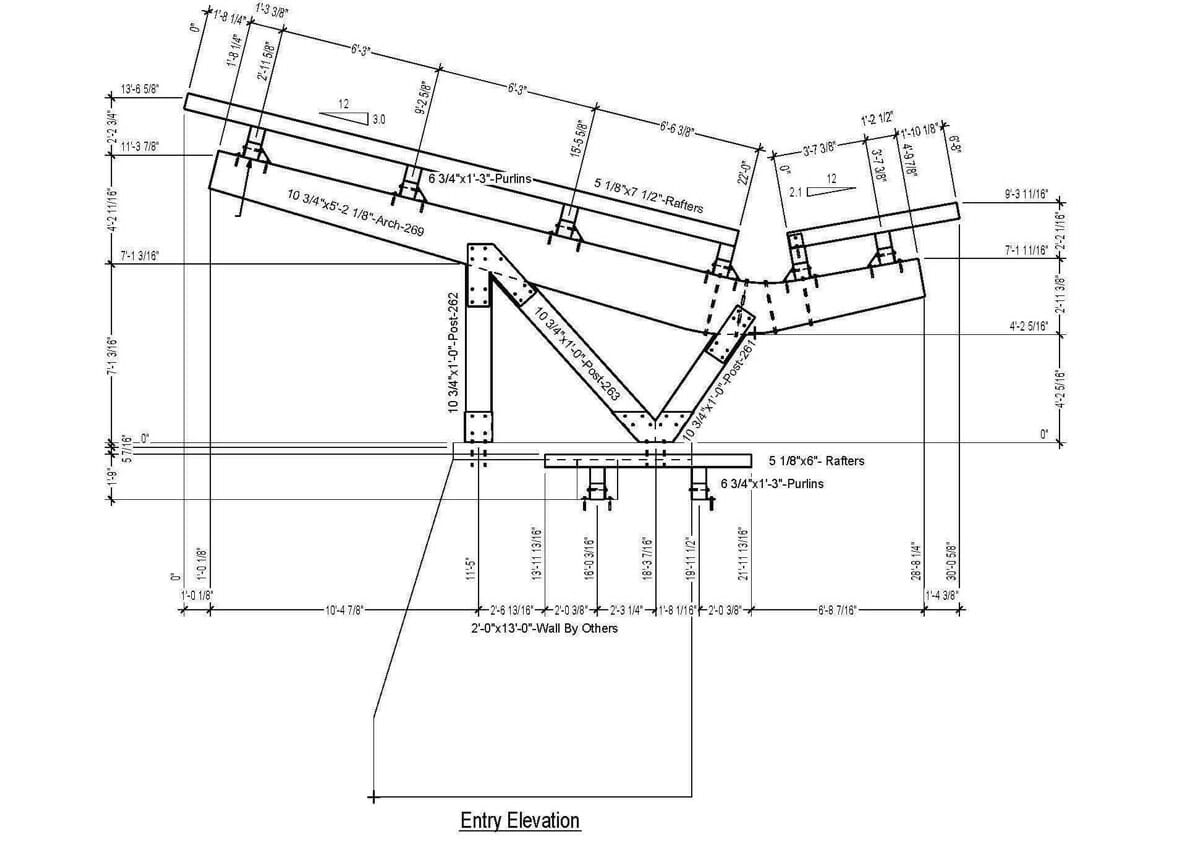

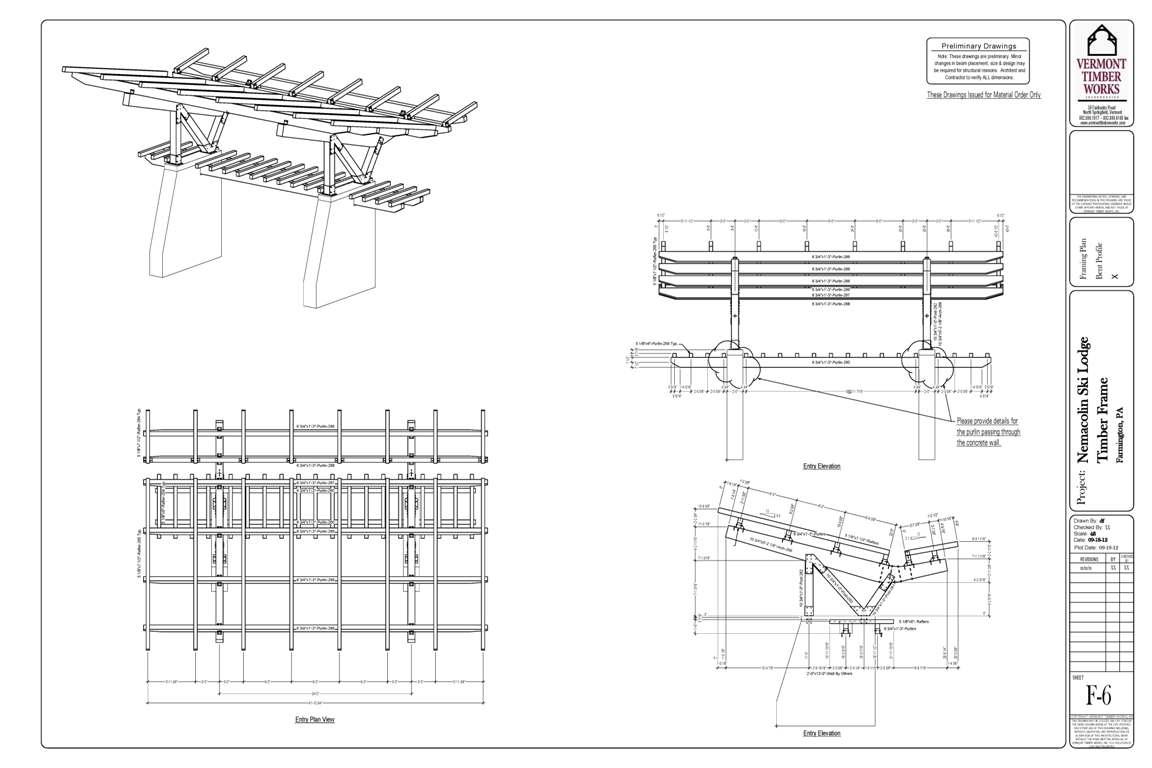

Timber Frame Entry / Boomerang

The entrance to the Nemacolin lodge has a timber frame pergola with glulaminated arched beams (a.k.a boomerangs). The straight timber pieces were not a concern for delivery time, but the boomerangs made us a bit nervous.

Entry Canopy

The frame was being constructed in our shop while construction onsite was underway. I recall many phone calls between myself and the general contractor checking in. “How’s it going?” “Glulams arrive yet?” “What about the Boomerangs?” “Timber columns shipped yet”?

Bring on the Boomerangs!

Did I tell you that we work well under pressure? Well. We do. And so do the Martik Brothers.

Finally!! The log columns arrived.

Hurrah! Now Hurry Hurry!

Heavy Timber Construction / Progress Shot

The completed Nemacolin Woodlands Sundial Ski Lodge is pretty awesome!

Sundial Ski Lodge

Nemacolin was a great project — stressful at times — but look at what we helped create!

Heavy Timber Canopy

We take tremendous pride in our work and truly appreciate all involved which include: Paul Cali DRS Architects, David Simpson from Allegheny Design Services and General Contractor Dean Martik from Martik Brothers (we’ve worked with Dean numerous times)!!

Sundial Ski Lodge / Roy Engelbrecht Photography

How’s that for a view from the slopes? NICE!

Thank you for stopping by our blog. If you like the frames in this post, or have any timber work questions, we invite you to get in contact, ask an expert, or share your thoughts in the comment section below!

Thanks for sharing this fantastic list of blogs.