Here is the moment you have all been awaiting: the #1 coolest timber frame (in my estimation) that Vermont Timber Works has built: the Chapel at Holy Apostles College and Seminary in Cromwell, CT. This frame consists of the main chapel area (which is a 60′ clear span octagon), a series of scissor trusses coming off three sides, and a timber frame porch at the entry. Check out the rest of The Top 10 Coolest Timber Frames (According To Me) here!

My personal favorite picture of Vermont Timber Works is this one of the octagon. You can see the scale of the building with the crew below–my recollection is that it is sixty feet to the peak of the bell tower.

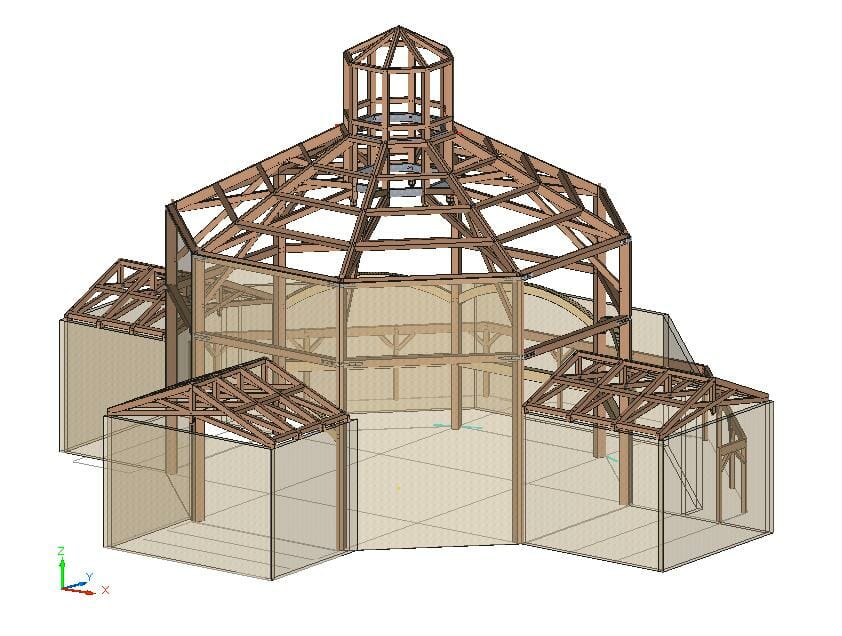

Our software can generate some very powerful presentations of what the timber framing looks like. For example, this 3d model is very clear as to the timber package, compared with one of the photographs below in this post.

Here are the timbers in our shop, ready for lay out and fabrication. Dan is, as usual, hard at work.

Dan and Rick are our main lay out guys, and confer with each other and with the prints to ensure accuracy. We have a system whereby the lay out world double checks the design world, and the cut crew double checks the lay out world. This system of double checking, and the excellent design work that goes on in the office, keeps errors to a minimum and involves all the craftsmen and craftswomen in the project. At VTW we have a tradition of a high level of craftsmanship and strive for perfection in our work.

Kellin and Rick are discussing specifics in the picture below. You can see our Hyster forklift (still going strong!) in the background.

Once the cut crew has checked the prints and the lay out for accuracy the timbers are fabricated using hand tools.

This picture of the job site was taken a few weeks before we were actually framing.

The process of the erection on this job is what I find to be the most cool. We set all eight columns with the corresponding connectors, glulams, etc. All of the curved arches and the heavier connectors below them in this picture were fabricated out of DF glulams. You can see the compression ring being fabricated on site by our steel fabricator Rick Crawford.

The compression ring had to be shipped to CT in pieces because it was too big to fit on a legal load tractor trailer. I am constantly amazed by what Rick can do with steel.

Once the ring was built and the cupola timbers attached to the ring, crane number one raised the cupola to the correct height.

While the cupola was held in place each of the eight trusses was flown in with another crane. You can imagine the coordination that was required for this to be pulled off smoothly.

At the end of the first day of flying in trusses we had to have four trusses installed to support the cupola, as the crane cannot hold a load overnight. That afternoon, all four trusses were in, and we freed up the first crane. We had measured from the deck to see how far the cupola would drop once the weight was taken off the crane, and if memory serves me right the cupola dropped by 1/16th of an inch.

The second phase of the project involved the installation of the scissor trusses (notice the intricate work on the finial king posts below) and the timber frame porch in front.

When we were done with the whole project you could how the timber framing looks related to the 3d isometric model.

Foard panel provided the panels to be installed over the timber frame. Sullivan Brothers General Contractors did a wonderful job with the rest of the framing, roofing, and siding.

You can see the glulam arches above the choir loft in this picture.

This shot is really cool, showing the inside of the bell tower.

Almost done!

The roofing for the chapel was a composite slate product, designed to look like real slate without the weight.

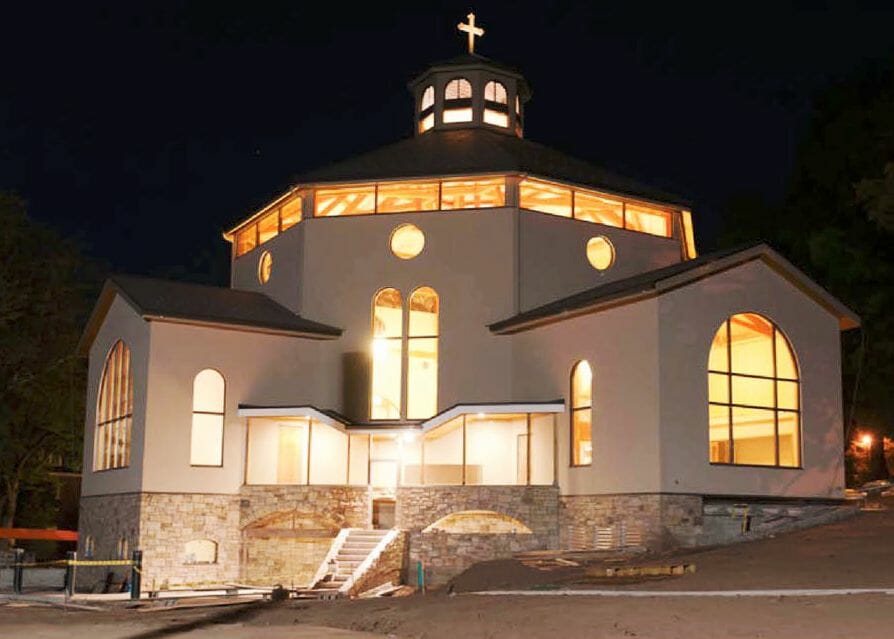

Here is an image, courtesy of the Holy Apostles College website, that shows the chapel after completion. What a beautiful structure.

Thanks for stopping by our timber framers’ blog! If you like this timber frame, or have any timber work questions, we invite you to get in contact, ask an expert, or share your thoughts in the comment section below!

very nice I love the design

Approximately how much it would cost ? Thanks

I have to say, that completed building looks a lot bigger than it did when just the framework was in place. A big part of that is probably from how thick each of those wooden beams is. Regardless of all that, it’s pretty neat to see the construction process of a building like that.

Thank you McKayla, we are glad you stopped by!

This looks like an incredible timber frame. I agree, the shot inside of the bell tower looks really cool. The finished product for any construction project is amazing to see, but the frames are one of my favorite things about seeing a new building come together. It looks like the skeleton of a building, so seeing how it looks as just the bare frame to when it all comes together is pretty amazing.

All that I can say is “Wow!” This isn’t something that you see every day, even in the timber frame world.