Well, another week of New England winter has passed by, the clocks have sprung forward (did you remember to change the batteries in your smoke and CO alarms?), and the evenings are getting longer. Up here in Vermont everyone is talking about how many trees they tapped, how many gallons of sap they have boiled, how great their set up is, etc. Sometimes I wonder if these guys with their sugaring operations are like fishermen and their tall tales…hmmm. Or maybe I’m just jealous because I haven’t tapped my trees yet. This week was perfect sugaring weather, so I’ve got to get out there this weekend and put in some taps.

Speaking of agriculture (from the Latin ager,agri field and cultura,-ae cultivation) leads me into what in my estimation is the 4th coolest timber frame Vermont Timber Works has built, the Brigham Hill Community Barn in Grafton, MA. The folks at Brigham Hill Community Farm are very civic-minded and grow fruit and vegetable crops for various hunger relief organizations. We were very glad to be a part of this project, along with our architect friends at Dixon Salo and our contractor friends at RH White Construction. Check out the rest of The Top 10 Coolest Timber Frames (According To Me) here!

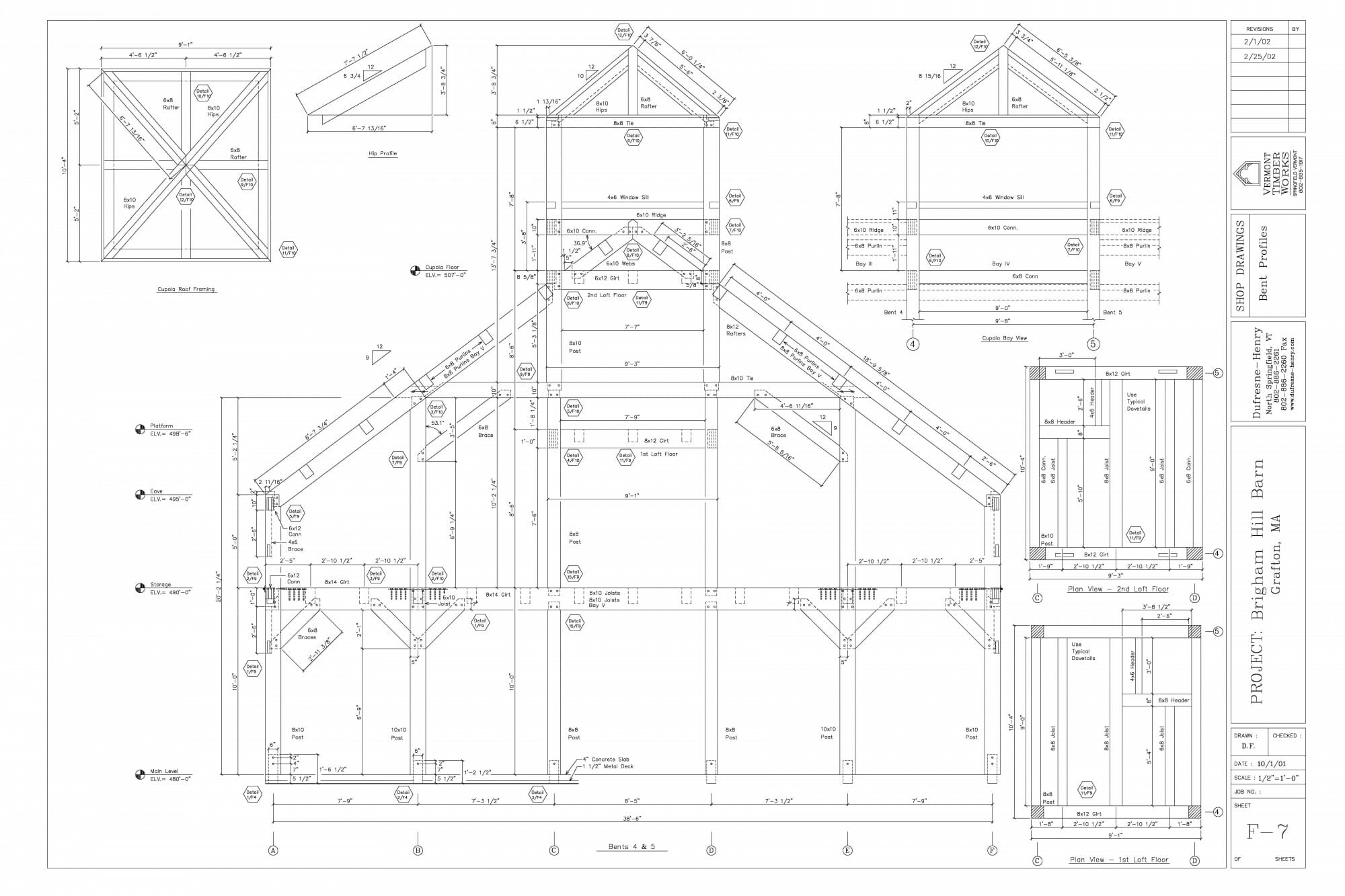

Our shop drawings are clear and concise as to what we are providing: roof pitch, post spacing, joinery details, etc. The shop drawing process is usually a two-pronged approach; one set is released for material order and the other set is released for fabrication.

This project used White Pine timbers for the timber framing. Eastern white pine is native to us here in New England, and looks good both rough sawn and planed and chamfered. This project happens to be rough sawn.

All of the timbers for the entire barn (with a footprint of 38′-6″ x 73′-8″) fit on two tractor trailers. We load the timbers onto the trucks at our yard in Springfield, VT; if we are raising the frame our crew will unload the timbers at the jobsite as well.

Frame up! That is the name of a book I read about the boat building trade on coastal Massachusetts, and I have glommed on to the expression. In any case, seeing the bents going up by crane is one of the coolest parts of timber framing, or construction in general. If you see this from afar, it’s enough to make you stop and watch for a few minutes.

We have put up a few frames in our time, so we know how to anticipate the next steps during raising, and move quickly to get the frames installed. This barn took approximately seven days from the day we got on site, to the time all the timbers were braced plumb and true.

All of our timbers are hand cut in the traditional way, using specialized timber framing tools. All of our craftsmen and craftswomen are skilled and know their way around timber joinery in this time-honored trade. It isn’t everyday that you see a timber frame barn built using this construction method, unless of course you happen to work here at Vermont Timber Works!

Scroll through the following pictures to see what the barn looks like now, very cool frame:

The fields are right outside the barn–I love it!

Thanks for stopping by our timber framers’ blog! If you like this barn frame, or have any timber work questions, we invite you to get in contact, ask an expert, or share your thoughts in the comment section below!

Can you tell me how much it cost to build this barn and what you had to do to prepare the land? It’s beautiful!

We are happy to give you some budget numbers for a frame like this one, give us a call to discuss your needs. 802-886-1917.